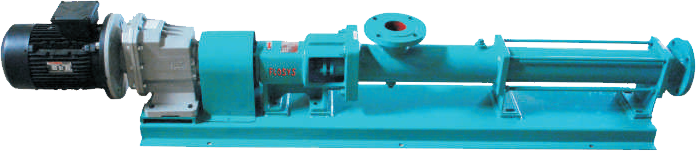

Flosys progressing cavity pumps are compact design, sturdy and powerful

Technical Specification

| Flow rate | : up to -500M/hr |

| Pressure | : up to-6,12,24,36,48 kg/cm |

| MOC | : Pump body CI, CF8, CF8M Wettable part AS,Ts,AISI 304,AISI 316 |

| Stator | : NBR, HNBR, EPDM, Hypalone, Neopene, Viton, Silicon |

Applications:

Acid and Alkaline slurry, Bentonite slurry, Casein slurry, Ferrite slurry, Detergent slurry, Digested sewage,

De-watered sludge, Water to thickened sludge,Polyelectrolyte, Sodium silicate, Sulphited suger juice,

Industrial wastes, Vegetables oil, Prining ink, Petrolem jelly, Resins, Alum,Black liquor, Magma,

Coating mix, Paint, Gum sludge, Emulsion, Flocculants, Glue, Grout mix, Lates, Massecuite, Viscose, Varnish,

Molasses, Oil sludge, Spentwash, Paperpulp, Stock etc.

Salient Features