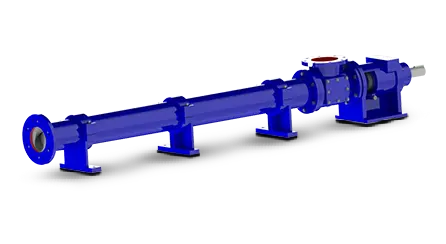

Retrofit of Progressive Cavity Pumps

We deliver pumps designed to handle precise applications with precision, reliability, and efficiency.

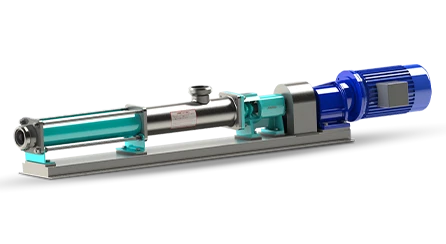

Flosys' progressive cavity pumps excel at smoothly moving fluids. We design our pumps to handle thick fluids & slurries with a steady flow and resistance to extreme temperatures. Retrofit progressive cavity pumps can handle sticky, non-lubricating, or even aggressive materials. Flosys Pumps is well-known for manufacturing such precision-engineered components along with retrofit spares to extend pump life even more, ensuring compatibility with leading global brands.

Being the leading progressive cavity pump manufacturer, Flosys achieves reliable performance with minimum operating costs by supplying precision retrofit parts and high-quality engineering.

Specifications of the Retrofit of Progressive Cavity Pumps

We design our progressive cavity pumps for a wide range of applications to ensure high performance. Its performance parameters are:

- Capacity : Up to 300 m³/hr

- Pressure : Up to 48 bar

- Viscosity Handling : Up to 1,000,000 cST

- Operating Temperature : 20°C to 150°C

Material of Construction

The rotor and stator are the core components of a progressive cavity pump, making it possible to achieve smooth and free-pulse flow. A universal joint connects the drive shaft to the rotor, enabling the transfer of torque while maintaining flexibility under varying loads. Other components, such as seals, bearings, and coupling rods, add to the durability and leakage prevention.

Product Ranges

- FSP Series Industrial Pumps : Designed to manage heavy-duty applications, such pumps can easily transport viscous, abrasive, and solid-laden fluids. Built to last, the pump assures consistent performance in industrial environments.

- FSH Hygiene Sanitary Hopper Pumps : These pumps, designed for the food and pharmaceutical industries, enable fully hygienic transfer of viscous products while maintaining product integrity and adhering strictly to safety standards.

- FSV Series Vertical Pump: Compact in design and space-saving, vertical pumps can be easily installed at sites with limited floor areas. Moreover, they guarantee consistent and reliable performance in continuous industrial operations.

- FM Series Pumps : The FM series pumps are flexible and effective, making them suitable for many fluid management tasks, ensuring strong performance for daily industrial use while being budget-friendly.

- FSS Series Hygiene Sanitary Design Pumps : Designed for hygienic processes, their surfaces are smooth, and food-grade elastomers make these pumps fit transfers from dairy to beverages to pharmaceuticals, where contamination-free flow is required.

- FSW Series Industrial Hopper Pumps: Designed specifically for moving materials with high viscosity or that contain solids, these hopper pumps feed and transfer materials without causing problems. They provide robust solutions to extreme industrial application processes.

- FL Frame Pumps: Frame-mounted pumps for structural stability and maintenance simplicity. Modular design allows speedy maintenance and uses for a variety of industrial applications.

- Retrofit Progressive Cavity Pump : Precision-engineered Flosys retrofit parts compatible with any global PCP brand have solutions for extending the life of pumps, reducing downtime, and ensuring cost-effective reliability.

Applications of Progressive Cavity Pumps

Every type of industry utilizes progressive cavity pumps for highly viscous and abrasive fluids, often containing solids. Flosys provides custom-designed upgrades and spare parts to enhance pump performance and reduce downtime by extending the lifespan of the pump and ensuring compatibility with international brands.

Key applications of progressive cavity pumps

Oil and gas industries

These pumps are used for transferring Syncrude crude oil, multiphase fluids, and drilling mud.

Food & beverage

The applications are vast and include the movement of viscous products like sauces, syrups, yogurts, and fruit pulp without disrupting texture.

Chemical processing

The medium consists of corrosive, abrasive, or shear-sensitive fluids that are difficult to handle.

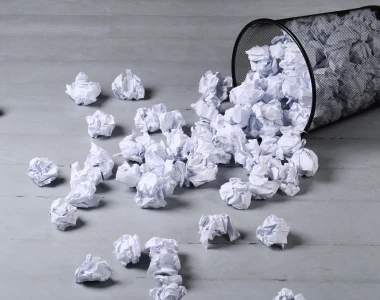

Paper & pulp industry

Transfers are no exception: slurries of pulp and coating materials.

Mining

This term refers to abrasive slurries, tailings, and mineral suspensions.

Pharmaceuticals

Gels, creams, and bio-slurries are pumped through hygienic ends designed for this purpose.

Benefits/Advantages of Flosys PCP

Progressive cavity pumps have gained trust for their smooth performance under every adverse condition. Gentle on the fluids they handle, with a consistent flow, they find space in almost all industries.

Flosys Pumps augments these attributes with accurate retrofits that will help save time and operational expenses while maximizing productivity.

Key Benefits

A pump is most suitable for pumping viscous fluids - it pumps thick, sticky, or semi-solid materials easily.

- Gentle pumping: It can preserve shear-sensitive products such as emulsions, creams, and biologics.

- Non-pulsating: assures constant delivery against changing pressure conditions.

- Handling solids: can pump fluids containing suspended solids without clogging.

- Versatile displacement capacity: suitable for applications at both low and high flow.

- Maintenance-friendly: long life, with few breakdowns, especially with the Flosys retrofit.

- Optimized hydraulic design: able to maintain the fluid dynamics with minimal energy loss.

- Resilience: Retrofit spares have been engineered with state-of-the-art machining and elastomers for durability and brand compatibility.

Frequently Asked Questions

Other Products

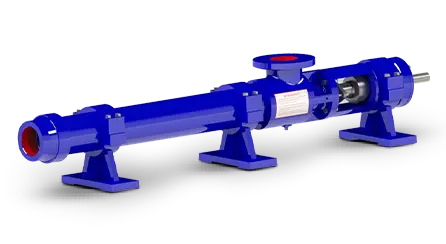

FSP - Series Industrial Pumps

These pumps are designed for rigid construction of cast iron with alloy steel / Stainless steel rotating parts. For corrosive Chemical applications, the pumps are of complete stainless steel construction.

FSS - Series Hygine Sanitary Design Pumps

These pumps are designed for hygiene applications. All the material parts in contact with the fluids are in smooth-finished stainless steel. The stators are of NON- NON-CONTAMINATED FOOD GRADE elastomers viz NBR, EPDM, SILICON & VITON.

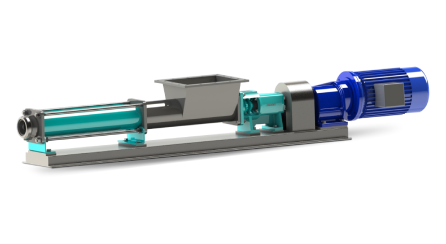

FSH - Series Hygine Sanitary Hopper Pumps

These pumps are constructed with STAINLESS steel housing (wide throat design) for high viscous & fiberous fluid transferring applications. The hopper type suction allows gravity flow of plastico-viscous material on to augur cum coupling rod pushes viscous substances in to pumping cavity.

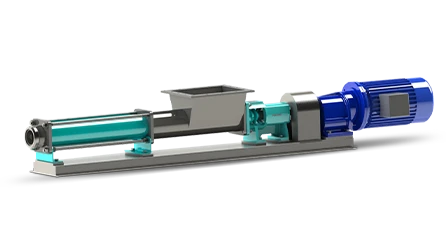

FSW - Series Industrial Hopper Pump

These pumps are constructed with a MILD STEEL wide-mouth hopper, and all the rotating parts are in alloy/ tool steel. For corrosive chemical transfer, the pumps are in complete Stainless Steel construction.

FSV - Series Vertical Pumps

These are compact and sleeve design vertical pumps driven by flanged-mounted prime movers for emptying the barrels.Various options in the joints, such as double-sealed bush/ pin.

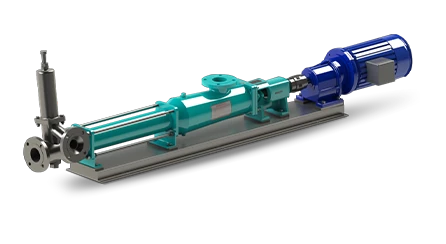

FL Frame Pumps

These pumps are identical to the L-Frame Progressive Cavity pumps and are available for a wide variety of applications. These pumps are offered with many different types of shaft sealing arrangements.